1. Industry background and special needs

Firefighting equipment (such as fire extinguisher tanks, fire hydrants, and hose interfaces) need to be exposed to high temperature, humidity, and corrosive environments for a long time, and the coating performance directly affects the life and safety of the equipment. In 2025, the EU "Firefighting Equipment Durability Regulation" (CPR) and ISO 12944-2025 standards will be implemented, which will put forward higher requirements for weather resistance, adhesion, and fire resistance of coatings. Data shows that the corrosion resistance of fire-fighting equipment using powder coating is increased by 3 times, and the service life is extended to more than 15 years.

2. Design principles and core goals

Weather resistance and safety

Select epoxy-polyester mixed powder coating, salt spray resistance test ≥1000 hours (in accordance with ISO 9227 standards).

The coating thickness is controlled at 80-120μm, and the adhesion reaches level 0 (ASTM D3359 cross-cut method).

Environmental compliance

Powder recovery rate ≥98%, VOC emission <10mg/m³ (in compliance with EU PPWR regulations).

Curing energy consumption is reduced by 25%, and infrared radiation heating technology is adopted.

Production efficiency

The modular design supports rapid switching of multi-specification equipment (changeover time <15 minutes).

Automated conveyor line beat optimization, single-line production capacity reaches 1200 pieces/hour.

III. Detailed explanation of process flow

1. Pre-treatment

Metal surface treatment:

Sandblasting (Sa2.5 level, in accordance with ISO 8501-1 standard) to remove rust.

Phosphating (zinc phosphating liquid) to enhance coating adhesion, film weight 5-8g/m².

Plastic surface treatment (such as fire extinguisher handle):

Plasma treatment (power 200W, time 5 seconds) to activate surface activity.

2. Powder spraying and curing

Electrostatic spray gun selection:

Manual spray gun: suitable for special-shaped parts (such as fire hydrant valve body), voltage 60-100kV adjustable.

Automatic spray gun: multi-axis reciprocating spraying, powder output accuracy ±3%, suitable for large-scale tank production.

Curing furnace design:

Infrared radiation heating (wavelength 2-10μm): quickly heat up to 180℃, keep warm for 20 minutes to ensure complete cross-linking of the coating.

Temperature uniformity ±3℃, air circulation system adopts frequency conversion control, uniformity deviation <8%.

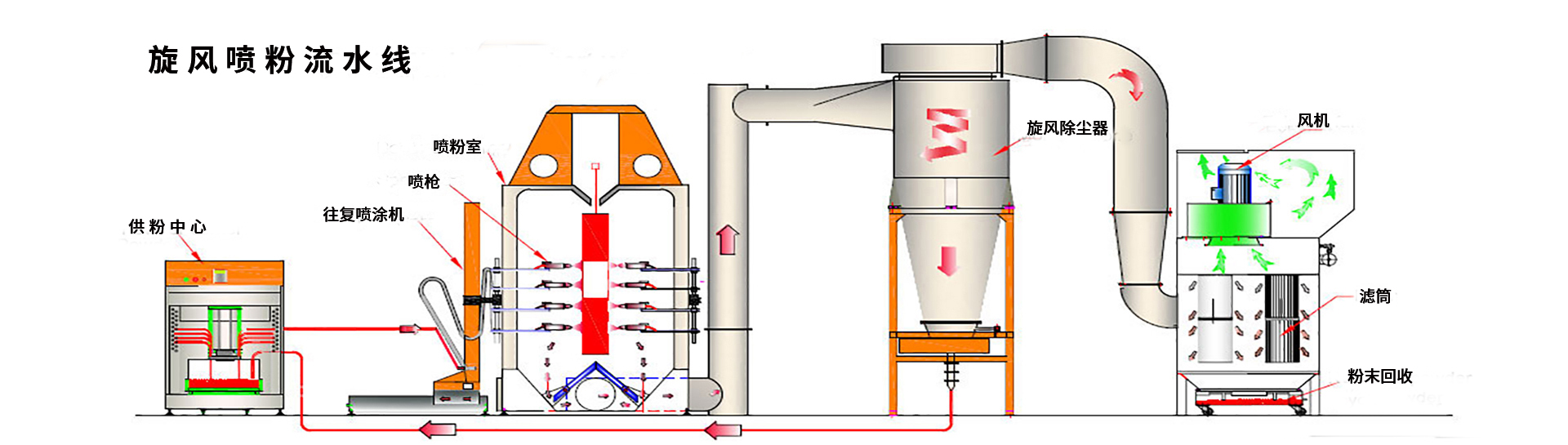

3. Recovery and post-processing

Multi-stage recovery system:

First-stage cyclone separator (efficiency 85%) + second-stage PTFE filter element (efficiency 15%), total recovery rate >98%.

The recovered powder is recycled after filtering through a vibrating screen (200 mesh), saving about 150,000 yuan per year.

Cooling device:

Water cooling unit (flow rate 10m³/h) reduces the temperature of the cured equipment to below 40℃ to prevent deformation.

IV. Environmental protection and safety measures

Waste gas treatment:

Catalytic combustion device (VOC removal rate 95%) ensures that the emission meets the standard (in compliance with EU EN 14175 standard).

Fire and explosion prevention:

The powder spraying room adopts explosion-proof motor (Ex dⅡC T6), static elimination device, and micro-negative pressure design (-15~-25Pa).

Operation safety:

Regularly maintain the equipment, train operators to master explosion-proof and first aid skills, and equip with AED defibrillator.

V. Quality control and certification

Testing standards:

Coating thickness (ISO 2808), adhesion (ASTM D3359), salt spray resistance (ISO 9227), high temperature resistance (250℃/2 hours without blistering).

Certification support:

Provide UL 795 (fire extinguisher certification) and CE-EN 671 (fire hydrant certification) test reports to help product exports.

VI. Case and data support

Case: After a fire equipment company upgraded its modular powder coating line, the changeover time was shortened by 70%, the single-line capacity was increased by 40%, and the annual VOCs emission was reduced by 8 tons.

Data: The efficient recycling system saves 150,000 yuan in powder costs per year; the intelligent scheduling system reduces idling time by 20%, saving 45,000 kWh of electricity per year.

Conclusion

Through international standard process design, weather resistance optimization and intelligent production processes, the powder coating line for fire equipment can achieve the dual goals of efficient manufacturing and certification compliance. In 2025, with the tightening of global regulations and technological innovation, modularization and digitalization will become the core direction of coating line upgrades. Enterprises need to keep up with the trend and plan ahead to gain an advantage in the competition.